О домостроении

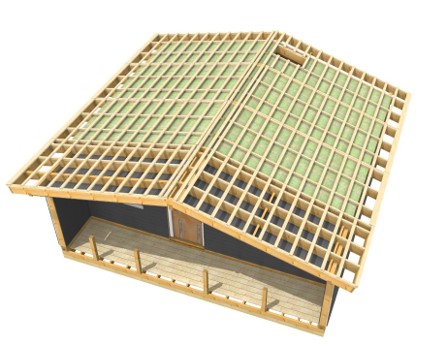

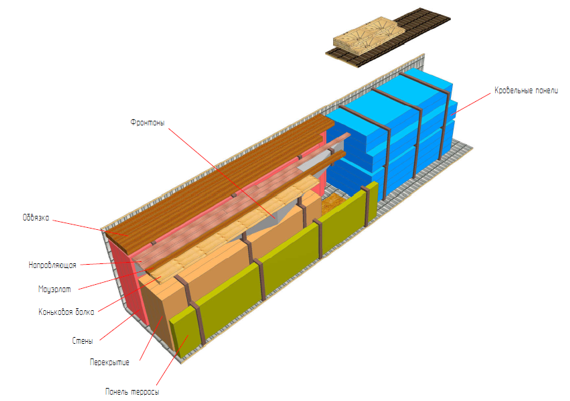

Каркасные и каркасно-панельные дома производятся на линии домостроения WEINMANN в цехе производства строительных конструкций завода «Терра». На линии осуществляется изготовление стеновых, цокольных, кровельных панелей, а также панелей перекрытия с закладкой утеплителя и пароизоляции для сборки домов (домокомплектов) по готовым проектам с максимальным уровнем внутренней и наружной отделки.

Производительность линии – 250 домокомплектов в год при работе в 2 смены. Линия WEINMANN сопряжена с программным обеспечением Sema.

Размеры производимых стеновых панелей:

• высота – до 3300 мм, длина – до 12000 мм;

• толщина стеновой панели – от 100 до 300 мм.

Параметры зависят от проектных расчётов и пожеланий заказчика.

На многофункциональном столе Optimat (линия сборки стеновых панелей) в цельном LVL брусе (плите) выполняются обработки различной степени сложности: отверстия, диагональные пропилы, пазы, выемки.

Размеры используемых заготовок, проходящих по параметрам станка:

• ширина – от 400 до 1250 мм;

• длина – от 1200 до 12000 мм.